|

n Technical principle

p Spray drying absorption (SDA) FGD is a technique in which liquid is atomized and sprayed into a drying tower as required to become powder under hot gas drying.

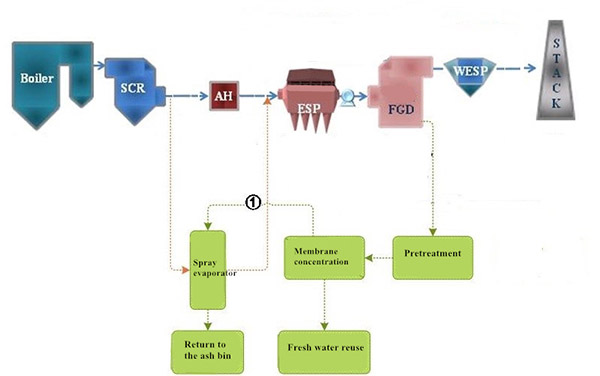

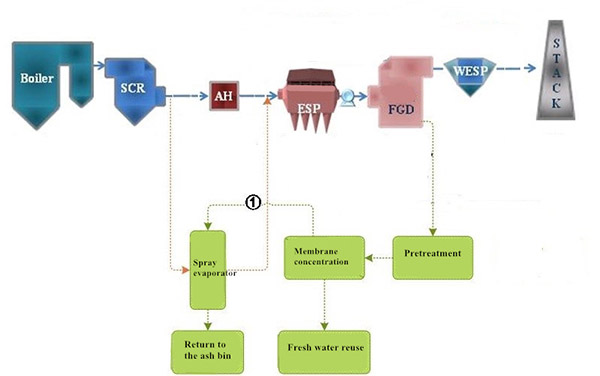

p Based on the principle of spray drying absorption, the spray drying method is applied to the treatment of desulphurization wastewater. The waste water is atomized into a drying tower with an average particle size of 10~60mm by rotating the atomizing disk. The hot flue gas in front of the air preheater is used as a heat source to evaporate the waste water in the spray drying tower, and the water enters the flue gas. The salt in the waste water is collected after drying, so as to achieve the goal of zero discharge of the desulfurized waste water.

n Process flow diagram

n Technical parameters

p The hot flue gas in front of the air preheater after denitrification of the boiler is used as the heat source.

p The moisture content of treated slag is less than 2%.

p The outlet flue gas of the drying tower is connected to the main flue before the entrance of the dust collector.

p The ash and salts from the lower part of the drying tower are pneumatically conveyed to the main ash conveying system of the electric precipitator of the power plant.

p The desulfurization wastewater is conditioned by lime or sodium alkali, so that the pH value of the wastewater can be controlled above 8.

p The control of desulfurization wastewater treatment system is integrated into the main DCS control system of power plant.

p The usability of desulfurization wastewater treatment device is more than 95%.

p The service life of desulfurization wastewater treatment unit is 30 years.

|