|

n System composition

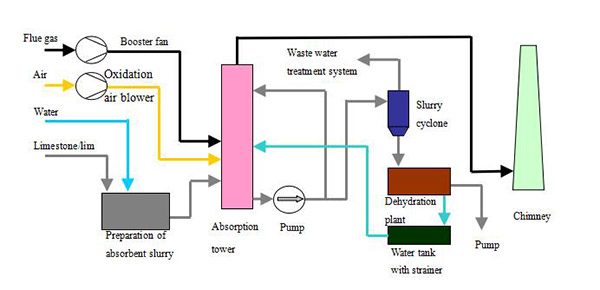

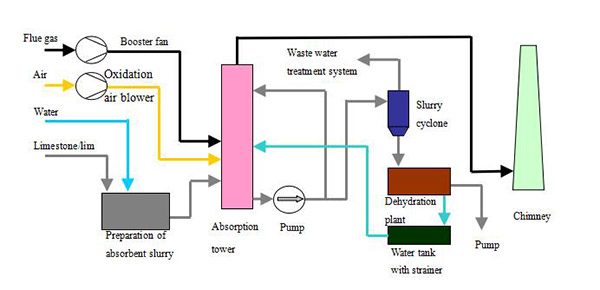

The limestone/lime-gypsum desulfurization system consists of an absorption slurry preparation system, a flue gas absorption and oxidation system, a desulfurization by-product treatment system, a desulfurization wastewater treatment system, an electrical control system, and an on-line monitoring system.

n Process flow diagram

n Technological process

The flue gas enters the absorption tower through the booster fan (the bottom of the absorption tower is the slurry tank), and the SO2 in the flue gas can be removed after contact with the slurry fed from the circulation pump. Fresh slurry is continuously added to the slurry tank at the bottom of the absorption tower. After being washed, the flue gas will enter the chimney after being defogged by the mist remover inside the tower.

The air is sent to the slurry at the bottom of the absorption tower through the oxidation fan, and the CaSO3 is oxidized into CaSO4. The slurry is sent to the slurry cyclone through a circulation pump to separate the water in the slurry, then sent to the wastewater treatment system. The underflow of the slurry cyclone enters the dehydration unit and is dehydrated gypsum after dehydration. The water dehydrated from the dehydration unit is filtered and sent to the absorption tower for reuse.

n Key Features

1) The process is mature, the operation is reliable, and the industry (especially in the flue gas desulfurization of coal-fired power plant boilers) is widely used.

2) Desulfurizer is cheap and rich in resources. The desulfurization efficiency can reach 95%.

3) Desulfurization by-products can be used.

4) There is wastewater generated during the desulfurization process, and the wastewater must be treated before being discharged.

5) The flue gas of the absorption tower is relatively humid, the flue gas is corrosive, and the absorption tower and its subsequent equipment, pipelines, chimneys, etc. are required to be treated with anti-corrosion treatment.

|