|

n System composition

The spray drying desulfurization system consists of a spray drying tower, a dust collector, an absorbent preparation system, a material conveying system, a desulfurization ash conveying and storage system, an electrical control system, and an on-line monitoring system. The process has two different atomization forms to choose from, one for rotary spray wheel atomization and the other for gas-liquid two-phase flow atomization.

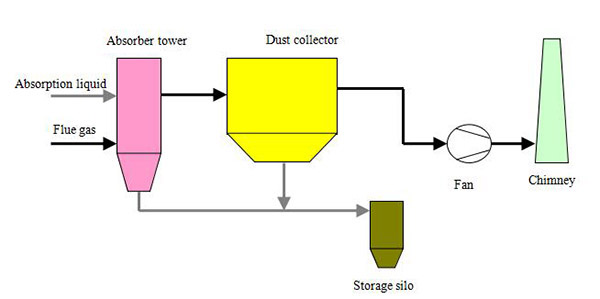

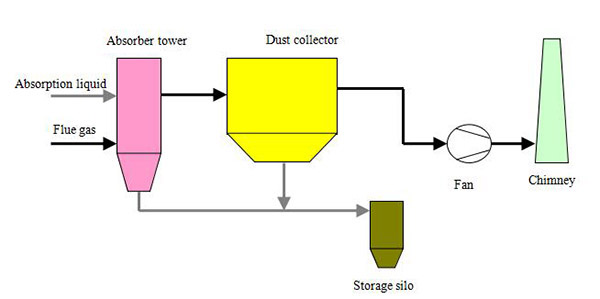

n Process flow diagram

n Technological process

The flue gas enters the spray drying tower and is in contact with the mist of the absorbing liquid atomized by the spray device, and the droplets of the absorbent are in full contact with the acid component in the flue gas to remove the SO2. After the flue gas is removed from the SO2, it enters the dust collector (electrostatic precipitator or bag filter) to remove soot and ash particles from the flue gas. The purified flue gas enters the chimney through the fan and is discharged into the atmosphere.

The atomization device in the spray drying tower has two different atomization forms to choose from, one is a rotary spray wheel atomization, and the other is a gas-liquid two-phase flow spray gun atomization. When atomized by a rotary spray wheel, both the flue gas and the absorbing liquid enter from the top of the spray drying tower.

n Key Features

1) The desulfurization efficiency is high, reaching 80-85%. The desulfurization by-product has good fluidity and is easy to handle.

2) It can quickly adapt to the change of flue gas flow, composition and concentration.

3) Low water consumption and no sewage.

4) The system is simple, the operation and maintenance workload is small, and the operation and maintenance costs are low.

5) The absorption tower and its downstream equipment will not be stuck or blocked, and no anti-corrosion is required.

|