|

n System composition

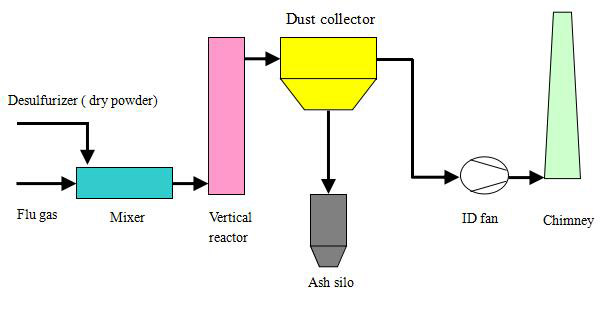

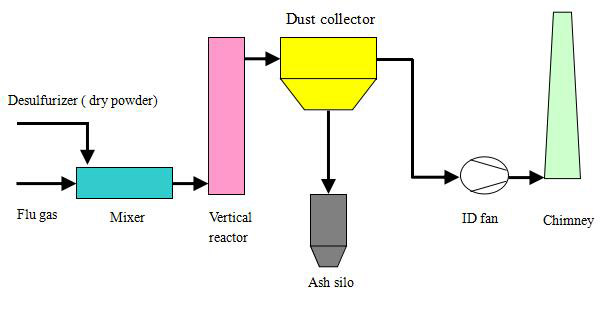

The dry desulfurization system consists of a mixer, a vertical reactor, a dust collector, an absorbent preparation and delivery system, a desulfurization ash delivery and storage system, an electrical control system, and an on-line monitoring system. See the process flow chart for details.

n Process flow diagram

n Technological process

The flue gas enters the mixer, in which it is evenly mixed with the dry powder of desulfurizer which comes from the absorber preparation system and meets the requirements in fineness. After mixing, it enters the vertical reactor. In the vertical reactor, the desulfurizer fully contacts with the acid components in the flue gas, removes SO2, and then enters the dust collector (Electrostatic precipitator or Bag filiter) to remove the smoke and dust particles in the flue gas. The purified flue gas enters the chimney through the fan and is discharged into the atmosphere.

The desulfurized ash captured by the dust collector is stored or reused in the ash silo through the desulfurization ash conveying system.

n Key Features

1) The process is simple and the system equipment is small.

2) The system has a small footprint and flexible layout, which is suitable for occasions where the site is in short supply.

3) The system does not use water, which is conducive to saving water resources.

4) The system does not have corrosion problems and does not require corrosion protection.

5) The desulfurization efficiency is related to the characteristics of the dry powder of the desulfurizer sprayed. When the sodium-based desulfurizer is used, it can reach 80%, and the purity and fineness of the desulfurizer are higher.

|