|

n System composition

The calcium - sodium double - alkali desulfurization system consists of an absorption liquid preparation system, an absorption tower, an absorption liquid circulation system, an absorption liquid regeneration system, a desulfurization by-product treatment system, an electrical control system, and an on-line monitoring system.

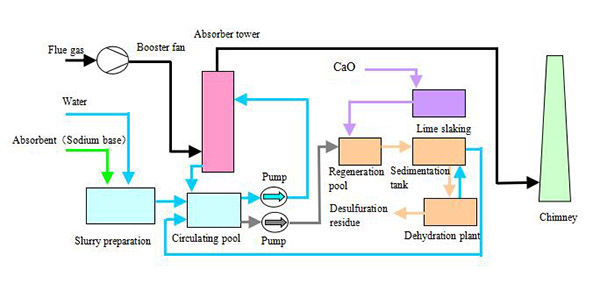

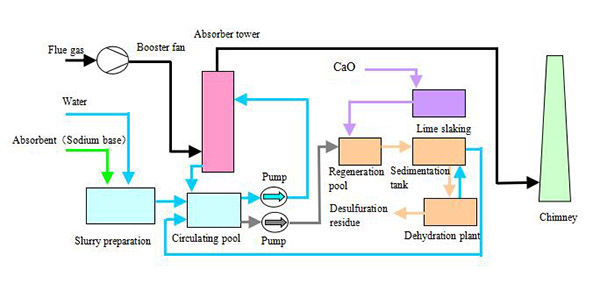

n Process flow diagram

n Technological process

The flue gas enters the absorption tower through the booster fan, and removes the SO2 in the flue gas after coming into contact with the absorption liquid fed from the circulation pump. The washed flue gas is defogged by the demister in the tower and then enters the chimney. The absorption liquid from the absorption tower is returned to the circulation pool for recycling. When the pH value of the absorption liquid in the circulation tank is lowered to the set value, the drain pump is automatically started, and the absorption liquid to be regenerated is pumped into the regeneration tank for regeneration (regeneration using lime slurry), and then enters the sedimentation tank for sedimentation. The supernatant of the sedimentation tank returns to the circulating tank, and the sediment (calcium sulfate and calcium sulfite) of the sedimentation tank enters into the dehydration device, and the substance ( wet/solid ) formed by the dehydration device is desulfurization residue, which is discharged periodically. The water discharged from the dehydrator is returned to the sedimentation tank.

During operation, fresh absorption solution should be added to the circulating tank regularly to supplement the sodium content in the absorption solution.

n Key Features

1) Mature technology, reliable operation and low investment.

2) The sodium absorption rate is high, the liquid-gas ratio is low, and the desulfurization efficiency is up to 95%.

3) The sodium base in the absorption liquid can be reused after being replaced by a calcium base, and the operation cost is lower than that of the sodium alkali method.

4) The flue gas of the absorption tower is relatively humid and corrosive, and the absorption tower and its subsequent equipment, pipelines, chimneys, etc. are required to be treated with anti-corrosion treatment.

|